TROWEL WALL

NEW & IMPROVED FORMULA

Trowel Wall is a decorative wall coating that incorporates a high-tech acrylic resin with natural marble stones. It creates a natural pebble wash effect with a neat appearance and a wide variety of colors that aesthetically enhances your property.

Trowel Wall has brilliant protection against ultra-violet rays, pollution, fungus, mold, and algae. It can be applied on a wide range of interior and exterior surfaces and niches such as plaster, concrete, bricks, wood, and gypsum.

Other Signature Products

Textured Coating

Brick Veneer

Wall Mix Overlay Stamp Concrete

Effect

Spray Coat

Stone Finish

Granules

Exposed Concrete Effect

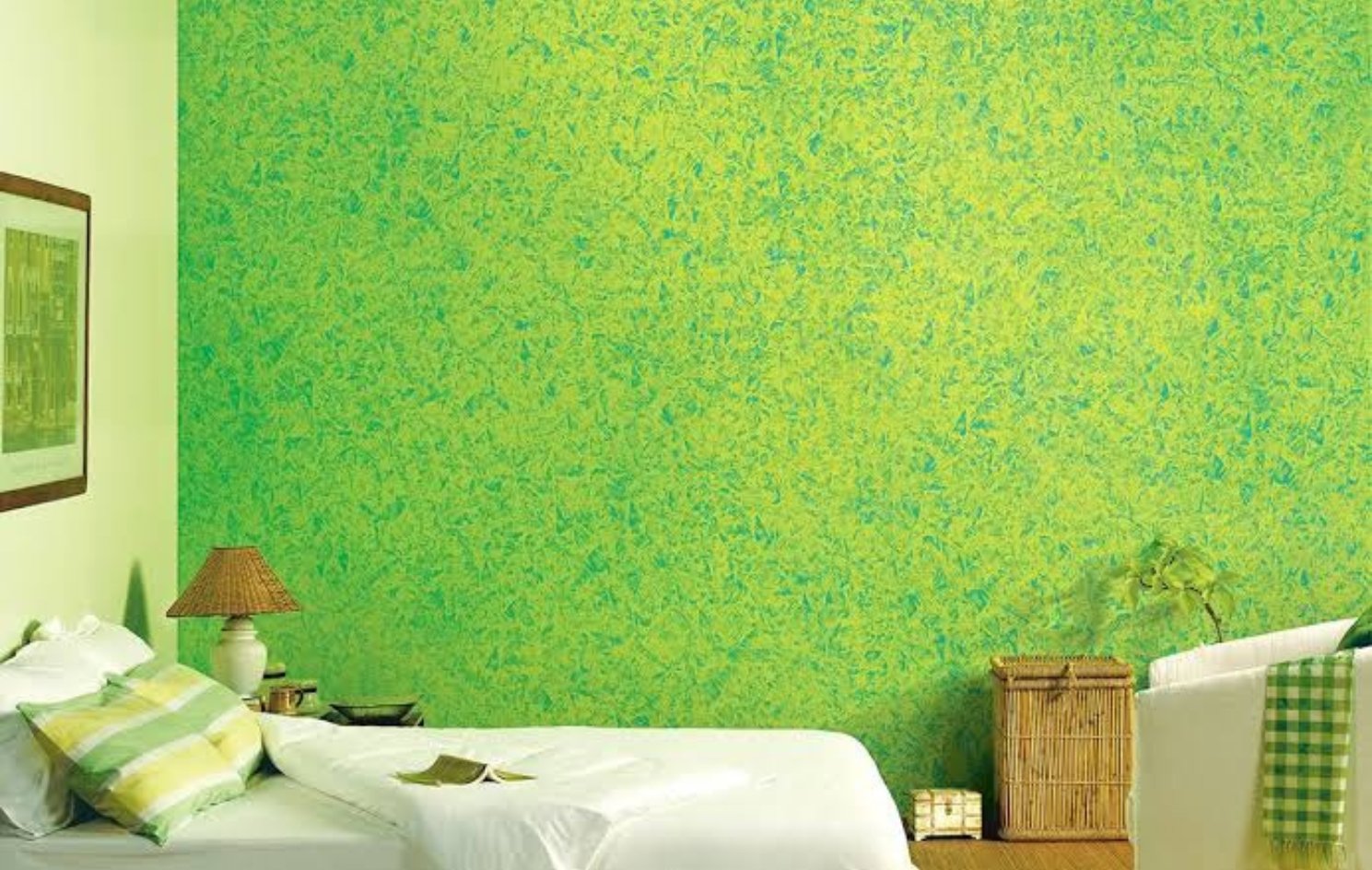

Interior Textured Paint

Trowel Pebble Stone Coating

Waterproofing

Roller Coat

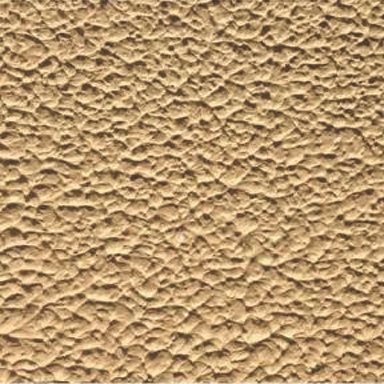

Coverage:

RC 140-150 sqf, 30 kg/bagThickness: 1.0 mm to 1.5 mm

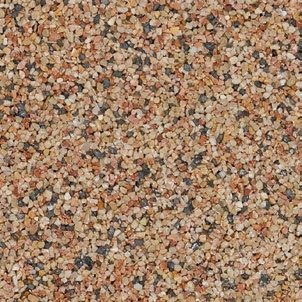

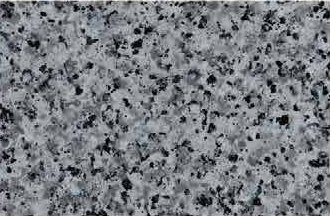

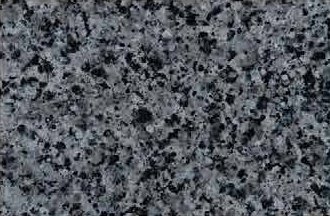

RC-001

RC-002

RC-003

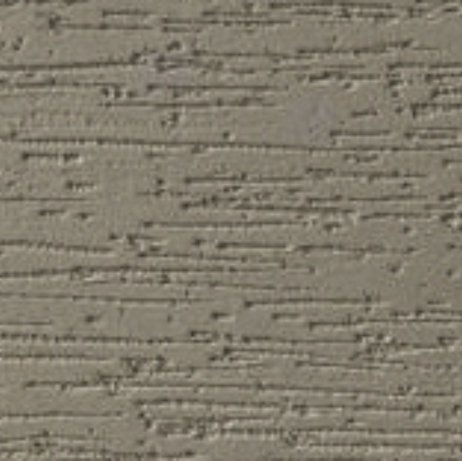

RUSTIC TEXTURE

Coverage:

RT 80-110 sqf, 30 kg/bagThickness: 1.5 mm to 3.0 mm

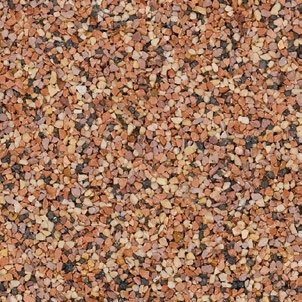

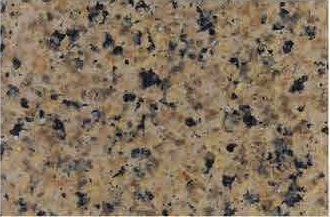

RT-001

RT-002

RT-003

RT-004

RT-005

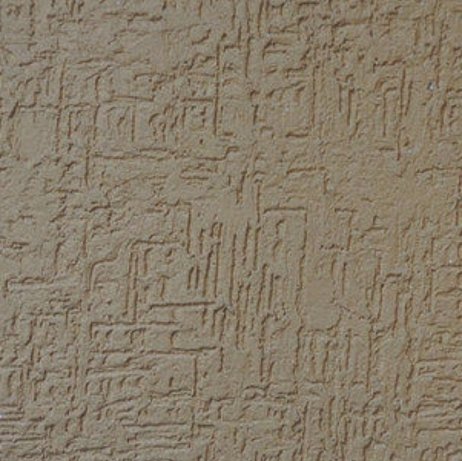

SPRAY COAT

Coverage:

SC 150-180 sqf, 30 kg/bagThickness: 1 mm to 1.5 mm

SC-001

SC-002

SC-003

SC-004

GRANULES

Coverage:

GF 140-150 sqf, 30 kg/bagThickness: 1.0 mm to 1.5 mm

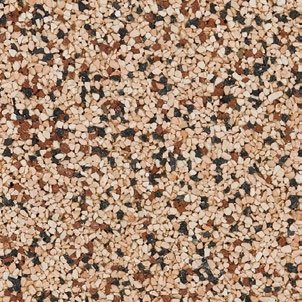

GF-001

GF-002

GF-003

GF-004

GF-005

GF-006

GF-007

GF-008

GF-009

GF-010

GF-011

GF-012

GF-013

GF-014

GF-015

GF-016

GF-017

GF-018

GF-019

GF-020

GF-021

GF-022

GF-023

GF-024

GF-025

GRANULA

Coverage:

GT 70-80 sqf, 30 kg/bagThickness: 1.7 mm to 2.0 mm

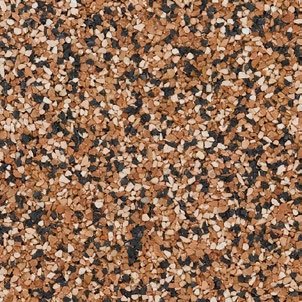

GT-001

GT-002

GT-003

GT-004

GT-005

GT-006

GT-007

GT-008

GT-009

GT-010

GT-011

GT-012

GT-013

GT-014

GT-015

GT-016

STONE FINISH

Coverage:

GT 150-170 sqf, 30 kg/bagThickness: 1.0 mm to 1.5 mm

SF-001

SF-002

SF-003

SF-004

SF-005

SF-006

SF-007

SF-008

SF-009

SF-010

SF-011

SF-012

SF-013

SF-014

SF-015

SF-016

SF-017

SF-018

SF-019

SF-020

SF-021

SF-022

SF-023

SF-024

SF-025

Trowel Wall (TW) Application

Surface Preparation:

All surfaces must be clean and free from loose or peeling paint, grease, dirt, dust, oil, and other foreign objects. Scrape or brush all loose paint off. Seal up any cracks and level uneven surfaces. The surface must be completely dry.

Absorbing Stage (IMPORTANT):

With regard to temperature and humidity, use a semi-dry roller (dipped in water and squeezed dry) to absorb any excessive resin on the surface. This is to get a clear appearance, avoid patchiness, and color difference.

Mixing Stage:

Add the appropriate amount of clean water (up to 0.3 litre) and mix SIGNATURE'S TW stones thoroughly with the resin before application. Mix manually with a clean stick.

Leveling Stage:

After 10–20 minutes, push the trowel onto all surfaces to compress them. Apply proper protection until the surface is fully dry (24 hours).

Undercoat (Optional):

Optional: Apply one layer of SIGNATURE'S TW-Primer before trowelling the stones on the wall, to facilitate a smooth application process. This is especially recommended for the C Series.

Topcoat Stage

It is recommended to apply a topcoat layer of Stone Care, either natural or glossy, after the surface has dried (after 24 hours). This helps enhance the protection of TW against dirt, oil, grease, water stains, fungus, mold, and weather conditions.

Trowel Stage:

Lay the prepared SIGNATURE'S TW on the wall with a clean stainless steel trowel. Remove all excess SIGNATURE'S TW stones (keep the trowel at an edged angle in order to level the thickness).

Curing Time:

-

Pot Life: 1 week

-

Touch Dry: 4 hours

-

Hardened: 24 hours

-

Final Curing: 3 days

CAUTION

.The material may loosen or detach from the surface if the application is too thick.

A stainless steel trowel is highly recommended to prevent rust stains adhering to the materials.

Different surfaces require different types of undercoat, i.e., wooden surfaces require a wood undercoat.

Trowel Stone products cannot be applied on glass or metal surfaces, underground or water-accumulated areas.

Always protect/cover the applied product during the curing period from wind, water, smoke, and rust till fully dried, i.e., canvas coverings.

As Signature uses all natural pebbles, we recommend making a one-time order to ensure color consistency.

Should you wish to apply different colors on the same surface, the use of groove lines is recommended to avoid joint problems.

Ensure application is complete edge to edge to avoid joint problems.

Do not apply under direct sunlight or rain.

Apply only when the floor temperature is above 13°C and under 32°C.

Do NOT apply within -15°C of dew point.

Interior concrete floors that do not have an effective moisture vapor retarder may possibly lead to moisture vapor transmission and related high levels of alkalinity which causes blistering and failure of the coating system.

New concrete requires 28 days cure and preferably a broom-swept finish prior to coating.

Please ensure the floor is fully dried (with no traces of moisture) before applying Signature TF.

Not recommended for driveways and heavy-duty use.