FLEX-C-MENT

NEW & IMPROVED FORMULA

Our "Overlay System" is in a league of its own! In the multi-billion dollar industry of concrete restoration and beautification, you will not find any other product that comes closer to the beauty and functionality of Decorcem "Overlay System".

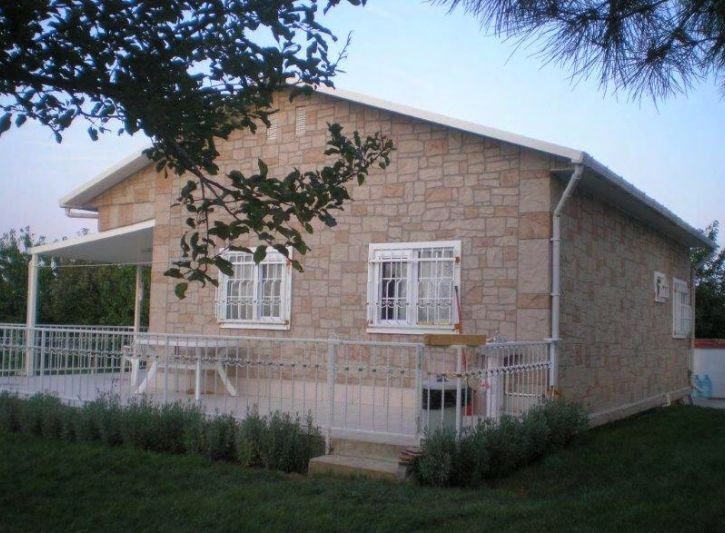

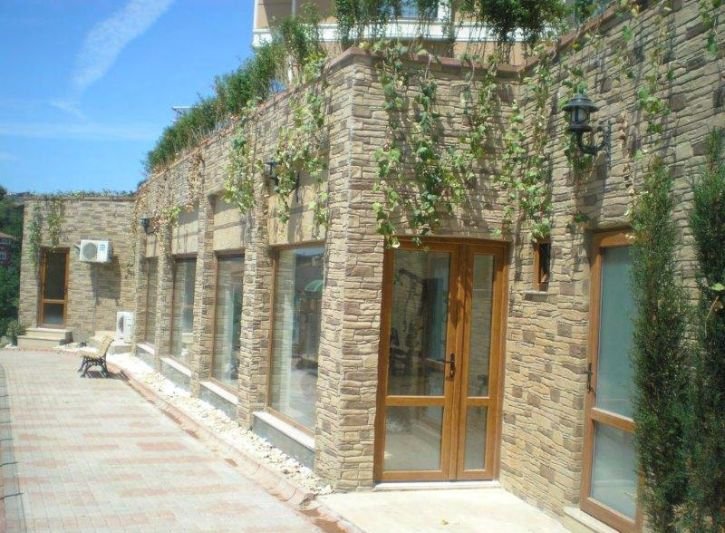

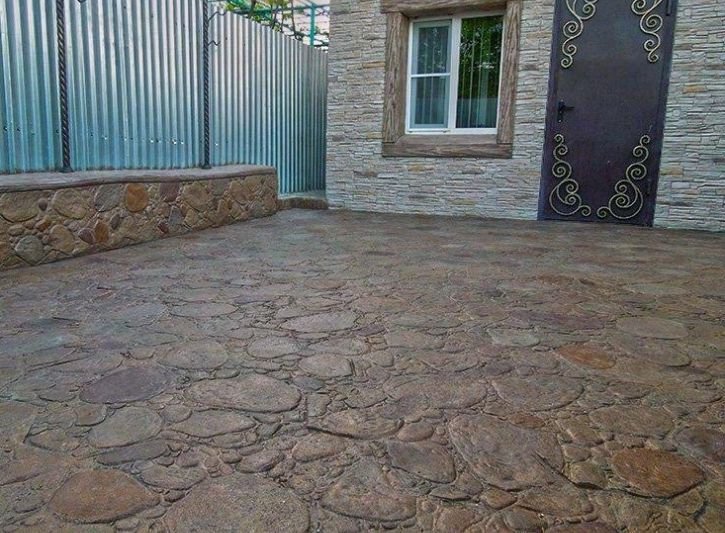

FLAX-C-MENT – Stone effects THE STAMPED CONCRETE: As the name signifies, Decorcem is a ready-mix concrete which adds beauty and drama to concrete floors, sidewalks, driveways, and other horizontal surfaces. It also beautifies and enhances the vertical surfaces, such as the walls of interiors and exteriors of our home, commercial places, landscapes, etc. All this is done by using the plastering, texturing, and colouring techniques to create structures, which exactly replicate natural stones, wood, bricks, and blocks.

In broad FLAX-C-MENT is a methodology involving special material, workmanship, special tools, and techniques to create deep textured very realistic model bricks, stones, and wood grain patterns. The special material includes the "Wall Overlay System". The lightweight concrete & "Floor Overlay System": The high dense concrete, available in various colours, which is applied by the highly skilled workers.

The application or installation is done with special tools, the plastered and stamped surfaces are then coloured randomly to bring the colours of natural stones & finally sealing the surface for long-term protection from external weather calamities.

TYPES OF OVERLAYS

WALL OVERLAYS

- Fireplace front

- Arched entryways

- Retaining walls

- Exterior walls

- Walls and partitions at parks and gardens

- Boundary walls

- Theme rooms in hotels and resorts

FLOOR OVERLAYS

- Driveways

- Parking Areas

- Jogging lanes

- Interior floors of rooms

- Porches

- Swimming pool areas

- Reception & waiting rooms of hotel lobbies

Floor overlays are highly dense & strong materials available in many natural colours. The stamped floor mix is randomly coloured and made to look antique.

The floor mix is sprinkled over the freshly poured concrete, which is then stamped to obtain the stone effects. Such stamped stones are then coloured randomly and made to look antique. The stamped floors are finally sealed for long-term protection.

WALL OVERLAYS

SW-001

GROOVED- STAMPED

APPLICABLE - WALL

THICKNESS - 20-25 MM

SW-002

GROOVED - STAMPED

APPLICABLE - WALL

THICKNESS - 15-20 MM

SW-003

GROOVED- STAMPED

APPLICABLE - WALL

THICKNESS - 15-20 MM

SW-004

GROOVED- STAMPED

APPLICABLE - WALL

THICKNESS - 15-20 MM

SW-005

GROOVED - STAMPED

APPLICABLE - WALL

THICKNESS - 15-20 MM

SW-006

GROOVED- STAMPED

APPLICABLE - WALL

THICKNESS - 15-20 MM

SB-104

GROOVED- 6 - 9 -12 MM TAPING

APPLICABLE - WALL

THICKNESS - 3-7 MM

SB-104

GROOVED- 6 - 9 -12 MM TAPING

APPLICABLE - WALL

THICKNESS - 3-7 MM

FLOOR OVERLAYS

SF-001

GROOVED- STAMPED

APPLICABLE - FLOOR

THICKNESS - 20-25 MM

SF-002

GROOVED- STAMPED

APPLICABLE - FLOOR

THICKNESS - 20-25 MM

SF-003

GROOVED- STAMPED

APPLICABLE - FLOOR

THICKNESS - 15-20 MM

SF-005

GROOVED- STAMPED

APPLICABLE - FLOOR

THICKNESS - 20-25 MM

SF-006

GROOVED- STAMPED

APPLICABLE - FLOOR

THICKNESS - 20-25 MM

SF-007

GROOVED- STAMPED

APPLICABLE - FLOOR

THICKNESS - 20-25 MM

SF-008/009

GROOVED- STAMPED

APPLICABLE - FLOOR

THICKNESS - 15-20 MM

SF-010

GROOVED- STAMPED

APPLICABLE - FLOOR

THICKNESS - 15-20 MM

SF-011

GROOVED- STAMPED

APPLICABLE - FLOOR

THICKNESS - 15-20 MM

SF-101

GROOVED- SKIN

APPLICABLE - FLOOR

THICKNESS - 10-15 MM

SF-102

GROOVED- SKIN/HAND CURVE

APPLICABLE - FLOOR

THICKNESS - 10-15 MM

SF-103

GROOVED- SKIN

APPLICABLE - FLOOR

THICKNESS - 10-15 MM

SF-101

GROOVED- SKIN

APPLICABLE - FLOOR

THICKNESS - 10-15 MM

SF-102

GROOVED- SKIN/HAND CURVE

APPLICABLE - FLOOR

THICKNESS - 10-15 MM

SF-103

GROOVED- SKIN

APPLICABLE - FLOOR

THICKNESS - 10-15 MM

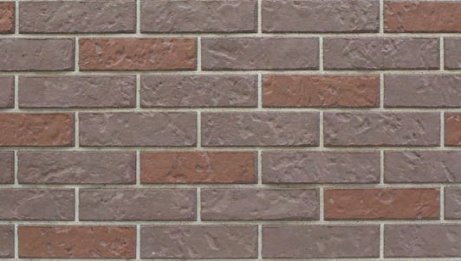

BRICKS

SB-105

SB-106

SB-107

SB-108

SB-109

SB-110

SB-111

SB-112

SB-113

SB-114

SB-115

SB-116

SB-117

SB-118

SB-119

SB-120

SB-121

SB-122

APPLICATION PROCESS ON WALL

STEP-1

Preparing wall for scratch coat

Plaster/concrete wall

STEP-2

Load thin material on wall

STEP-3

Draw scratch coat

STEP-4

Remove excess material

STEP-5

Load material as plaster for stamping in required thickness

STEP-6

Stamping Dye in interlocking manner

STEP-7

Completed Stamping

STEP-8

Scrapping excess material

STEP-9

Applying accent enhancer

STEP-10

Applying colours randomly

STEP-11

Washing with colour to achieve antique look

STEP-12

Final view

APPLICATION PROCESS ON FlOOR

STEP-1

Raw space

STEP-2

PCC flooring

STEP-3

PCC Leveling

STEP-4

PCC finishing

STEP-5

Sprinkling colour hardner

STEP-6

Stamping

STEP-7

Stamping

STEP-8

Finishing stamping

STEP-9

Final view of stamping

STEP-10

Colouring or washing & eaching

STEP-11

Final view after top coating